10 Dec 2024

What Are the Different Types Of Industrial Pipes And Ball Valves?

Within the expansive network of industrial systems, there is a need for a seamless flow of liquids and gases across diverse industries. That is where industrial pipes and ball valves are two components that play a pivotal role. Piping systems are integral to the efficient functioning of industrial processes. They help in maintaining the proper flow rates, pressures, and temperatures required for different manufacturing processes, contributing to overall operational efficiency.

Importance of Industrial Pipes

Industrial piping systems form the backbone of various industrial processes, including chemical production, oil and gas refining, and power generation. Properly designed and maintained piping systems contribute to process optimization and enhance overall operational reliability. Thus, industrial piping systems are essential components that facilitate the seamless functioning of diverse industrial sectors, impacting productivity, safety and the overall economic landscape.

Industrial pipes serve diverse sectors:

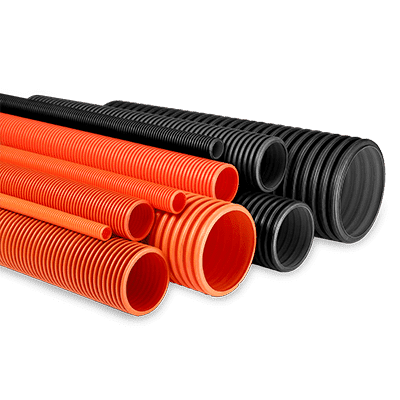

Industrial pipes serve diverse sectors such as construction, where PVC pipes, are utilized in residential, commercial, power, water, and manufacturing structures. In agriculture, polyvinyl chloride (PVC) pipes facilitate water transport from urban centres to farms.

The automotive industry relies on industrial tubes for process utilities, and in mining, plastic pipes are employed for conveying water, chemicals, slurry, and various fluids. In aerospace, spiral welded coated pipes are used in hydraulic systems for flight control surfaces and landing gear. The pharmaceutical sector depends on sanitary pipe fittings and tubing for processes like chemical extraction and material processing.

Additionally, industries like oil and gas, petrochemical, chemical, power, food and beverage, HVAC manufacturers, steel manufacturers, pipeline manufacturers, and plumbing manufacturers also heavily rely on

Different Types of Industrial Pipes and Fittings

Astral Pipes manufactures a range of industrial pipes and ball valves that are a part of various piping systems in several industries. First, let us explore the different types of industrial pipes and ball valves, and learn about their uses and how they keep modern industrial functions running.

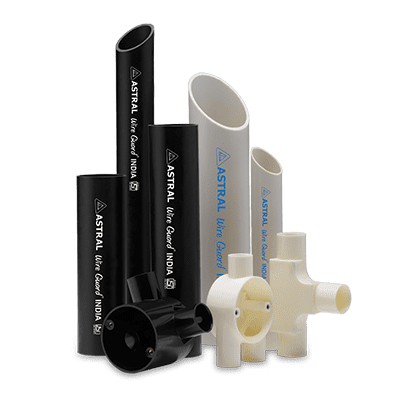

Industrial Pipes and Fittings by Astral Pipes

- Astral Chem Pro

- Astral ChemPro is a reliable CPVC piping system for industries, meeting tough requirements

- It handles temperatures up to 93°C (intermittently up to 110°C) and various pressures.

- Ideal for industrial needs like metal treating, food applications, wastewater, and chemicals. Astral Limited is the exclusive Indian manufacturer of industrial CPVC pipes, offering sizes from 1⁄2” to 12”.

- Our pipes conform to ASTM standards, ensuring durability and compliance with environmental standards.

- In aggressive chemical environments, Astral ChemPro prevents corrosion, leaks and premature failure, ensuring long service life and minimal downtime for industrial firms’ success and growth.

- Astral Chem Pro has applications in Industries like pharmaceutical, chemical processing, sugar industries, food and beverage industries, steel industries, mining industry, power sector, industrial waste treatment, etc.

- Astral Aquarius+

- Astral Aquarius+ is a lead-free uPVC industrial piping system that meets ASTM standards.

- These pipes and fittings ensure easy installation and a trouble-free lifetime of service.

- They are available in sizes from 1.5 cm to 30 cm, in SCH 40 and SCH 80 classes, offering versatility for various industrial applications.

- Astral Aquarius+ has applications in industries like water treatment plants, pulp and paper industries, fertiliser industries, shipping industry, food and beverage industry, chemical processing, etc.

What are Ball Valves and Their Uses In Industrial Piping Systems?

Ball valves are mechanical devices used in industrial piping systems to control the flow of liquids or gases. They consist of a spherical closure element (the ball) with a hole for fluid passage. When the valve is open, the hole aligns with the pipeline, allowing smooth flow, and when closed, the ball rotates to block the passage, halting the flow. Ball valves are crucial for regulating fluid flow, isolating sections of a pipeline and ensuring efficient and precise control in industrial processes.

Thermoplastic Ball Valves by Astral Pipes for Industrial Pipe Fittings

Astral Pipes offers a range of ball valves for industrial piping systems. They are easily removable and can be fully serviced under pressure in the closed position. Rigorous quality control ensures reliability in all conditions. Available in uPVC and CPVC to complement Astral’s piping systems, Aquarius+ and Chem Pro, making us the leading one-stop solution for industrial piping needs.

- True Union Ball Valve: The Astral’s Industrial True Union ball valve is a highly advanced valve with cutting-edge features. It is widely used in applications involving acids and corrosive chemicals instead of stainless systems for increased corrosion resistance. These valves find application in chemical processes, aggressive acid environments, mining, mineral processing, pulp and paper industries, plating and metal treatment. With smooth operation and low torque, they provide trouble-free service and a long lifespan.

- Single Union Ball Valve: The Astral Single Union ball valve stands out with advanced manufacturing as one of the most advanced options in the market. It is ideal for Irrigation, pool/spa, farming and non-critical applications, offering high performance through quality components.

- Compact True Union ball valve: The Astral Compact True Union ball valve is a valve designed with advanced features. It is ideal for residential, commercial and many industrial applications, providing smooth operation with low torque and full pressure rating for trouble-free service and a long lifespan.

It is important to select the appropriate type of pipe and valve based on factors like the type of fluid, pressure, temperature, and the specific requirements of the industrial process.

-

16 Apr 2025

How to Install Water Tank? -

09 Apr 2025

Plastic Pipes vs Copper Pipes: Which One is Better for Plumbing? -

04 Apr 2025

Astral Pipes: Innovation, Quality, and a 25-Year Warranty You Can Trust -

31 Mar 2025

How to Calculate the Right Capacity of Your Home Water Storage Tank? -

25 Mar 2025

Why CPVC Pipes are the Best Choice for Hot Water?