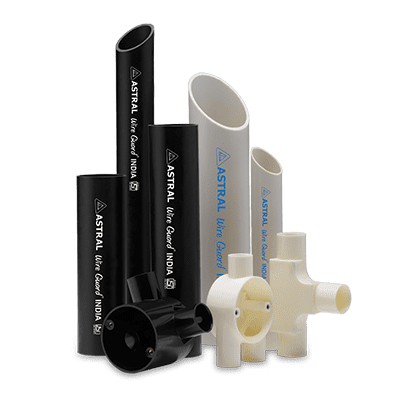

Features of uPVC Pressure Pipes

- Astral Aquasafe uPVC pressure pipes for potable water transportation and agriculture are manufactured using high-quality raw materials to ensure durability and reliability.

- The pressure pipe exhibits excellent chemical resistance, which makes it suitable for a wide range of applications, including handling acidic and alkaline substances in water.

- This piping system’s superior flow capabilities enhance efficiency to deliver optimal yields for agricultural and domestic use.

- Designed with a selfit jointing system, these pressure pipes provide a leak-proof solution that ensures seamless performance under pressure.

- Manufactured using advanced machinery, Astral Aquasafe agriculture pipes guarantee consistent quality and adherence to the highest industry standards, which makes them a dependable choice for various water transportation and drainage needs.

Key Properties of uPVC Pressure Pipes

- High Corrosion Resistance: Astral Aquasafe pressure pipes and fittings are engineered to resist corrosion effectively, as they are non-reactive to acidic and alkaline substances in water.

- Low Maintenance: The innovative selfit jointing system ensures a leak-proof and efficient solution, enabling better flow and offering maintenance-free performance for years, which makes Astral Aquasafe pressure pipes a hassle-free choice for long-term use.

- Conductivity: As non-conductors of electricity, Astral Aquasafe pipes provide enhanced safety by preventing electrical shocks, making them a secure option for water transportation systems.

- Strength and Quality: These uPVC pressure pipes are manufactured using premium-quality raw materials and under stringent quality standards to ensure high strength, durability, and an extended life cycle, making them a reliable choice for diverse applications.

- UV Stabilised: Designed to withstand outdoor conditions, Aquasafe agriculture pipes and fittings are UV-stabilised, maintaining their performance and structural integrity under prolonged exposure to sunlight.

- Easy to Install: These pressure pipes are lightweight yet made with strong material. Astral Aquasafe is easy to handle, transport, and install, ensuring convenience and reliability.

Uses of Pressure Pipes in Different Areas

Astral Aquasafe pipes are versatile, with applications such as agriculture, irrigation, water supply, industrial process lines, and swimming pools. This uPVC pressure pipe outperforms CI, GI and RCC pipes by offering several advantages.

SYSTEM SELECTIONS AND INSTALLATION GUIDE

- Velocity and Pipe Size Selection

For an efficient pipeline design, the fluid velocity is optimised at 1 m/s. Use the flow diagram provided, based on the Hazen-Williams formula, to select the appropriate pressure pipe size at the intersection of this velocity (1 m/s) and the discharge in litres per second (LPS). Once the pipe size is determined, calculate the frictional losses for that specific size.

- Pressure Class Selection

To determine the appropriate pressure class for the pipeline, calculate the total head acting at the point of interest using the following formula:

Total Head = Frictional Head + Static Head + (10% of the sum of Frictional Head and Static Head)

- The additional 10% accounts for head losses due to valves and fittings.

- Multiply the total head by the corresponding length of the pipe to obtain the pressure head value.

- Pump Selection for Pressure Pipes

Determine Pump Horsepower (HP)

Use the following formula to calculate the required pump horsepower:

HP of Pump = (Discharge × Head) / (75 × η)

Where:

- Discharge is the flow rate.

- Head is the total head in meters.

- η is the efficiency of the pump, typically 65%.

Once the pump HP is determined, select a pump model with specifications that closely match the calculated horsepower from the manufacturer’s catalogue. After selecting the pump, re-evaluate the pipeline’s pressure class by recalculating the pump’s effect on the total head. Ensure that the pipe’s pressure class is suitable for the updated conditions to maintain system reliability.

- Water Hammer

Water Hammer refers to a surge in pressure that occurs when the flow rate of fluid in a pressure pipe changes suddenly. This hydraulic shock is more pronounced in longer pipelines and at higher fluid velocities. Common causes of water hammer include the abrupt opening or closing of valves, starting or stopping pumps, or the movement of trapped air within the pipeline.

For design calculations, water hammer pressure is typically disregarded due to the high modulus of elasticity of PVC material, which helps mitigate the effects of such pressure surges.

AIR VALVE SELECTION AND INSTALLATION

Although the pressure pipe size and pressure class selection are accurately calculated, the proper selection and installation of air valves are crucial for ensuring optimal functionality. The combination of air and water can be particularly harmful to uPVC pressure pipes. Due to its compressible nature, air tends to accumulate in the pipeline if air valves are not functioning properly. This accumulation results from transient changes in localised velocity, leading to the generation of high localised pressure that cannot be detected using a conventional gauge.

To mitigate this issue, high-quality air valves should be installed. Air valves are available in two types: single-acting and double-acting.

Important Information About Air Vales

- Placement of Air Valves: Air valves should generally be installed at all peak points in the pressure pipe system, spaced approximately 300–400 meters apart.

- Size and Location: The size and location of air valves should be determined in consultation with an engineer. For optimal performance, the size of the air valve should be between ¼ and ⅙ of the pipe’s diameter, ensuring smooth air admission and release.

- Type of Air Valves: Only double-acting air valves should be used at peak levels to ensure efficient operation.

- Protection of Air Valves: It is recommended to construct protective chambers around air valves to safeguard them from external damage.

- Additional Requirements: Air valves should also be installed at points where the flow’s direction or velocity changes.

How to Install UPVC Pressure Pipes with Selfit Installation Procedure?

Step 1: Cut the Pressure Pipe

Ensure the pipe is cut squarely. Since the joints are sealed at the base of the fitting socket, an angled cut may compromise the integrity of the joint, potentially leading to failure.

Step 2: Remove Burr and Bevel

Use a knife-edge file or a deburring tool to remove all burrs from the inner and outer edges of the pipe. Chamfer (bevel) the pipe end at an angle of 10°–15°. Clean the pipe’s surface thoroughly using a dry cloth to remove any dirt, grease, or moisture.

Step 3: Dry Fit

Test the fit by inserting the pipe into the fitting socket with light pressure. The uPVC pressure pipe should slide one-third to halfway into the socket. Do not use pipes and fittings that feel excessively tight or too loose.

Step 4: Apply Primer and Solvent Cement

Use primer to penetrate and soften the pipe and fitting surfaces, enabling a strong fusion. For heavy-bodied solvent cement, apply primer before cement application. Coat the agriculture pipes’ exterior with a full, even layer of cement and apply a medium layer to the fitting’s interior.

Step 5: Join Pipe and Fittings

Push the pressure pipe into the fitting socket until it makes contact with the socket’s base. Hold the pipe and fitting in position to prevent the pipe from backing out. Wipe off any excess cement from the exterior. A properly formed joint will display a continuous bead of cement around its perimeter, ensuring a secure seal.

This method ensures durable and leak-proof joints for your uPVC pressure pipes.

Adhesive Solutions for Aqusafe uPVC Pressure Pipes

For optimal performance, always pair Astral Aquasafe Solvent Fitted Pipes with Astral fittings and join them using Astral PVC cement solution. The Astral Pipe Fix uPVC 206 solvent cement is the most suitable for Aquasafe pressure pipes. Our Pipe Fix solvent cements for PVC and CPVC plastic piping systems are renowned for their low Volatile Organic Compound (VOC) content. These cements are of the highest quality and are widely recognised as the ideal solution for joining PVC, uPVC pipes and CPVC pipes and fittings.

The quality of solvent cement is important to ensure durable joints. Therefore, it is strongly recommended to use only high-quality solvent cement. Avoid using solvent cement that is old, hardened, or semi-fluid.

For pressure pipe with a diameter of 125 mm and above, regardless of the class, always use heavy-bodied solvent cement uPVC 717. Additionally, always apply Primer P70 in conjunction with heavy-bodied solvent cement uPVC 717 to ensure superior adhesion and long-lasting joints.

How to Install Aqusafe UPVC Pressure Pipes with Ring Fit Installation Procedure?

Step 1: Cut the Pipe

Ensure the pipe is cut squarely, as the joints are sealed at the base of the fitting socket. Angled cuts can compromise the joint and lead to failure.

Step 2: Remove Burr and Bevel

Use a knife-edge file or a deburring tool to remove all burrs from both the inside and outside of the pressure pipe. Bevel (chamfer) the pipe end at an angle of 10°–15°. Clean the pipe’s surface thoroughly with a dry cloth to eliminate any dirt, grease, or moisture.

Step 3: Insert the Pipe

Insert the agriculture pipe into the socket without the rubber seal ring. Push it fully in and mark the insertion depth on the pipe.

Step 4: Fix the Rubber Ring

Place the rubber ring into the groove of the fitting socket, ensuring it is seated properly without any twists.

Step 5: Apply Lubricant

Apply a jointing lubricant to the chamfered end of the pipe and the rubber ring, extending up to the mark on the spigot or the socket end of the fitting.

Step 6: Join the Pipe and Fittings

Push the pressure pipe firmly into the socket until the gap between the mark on the spigot and the socket is approximately 10 mm. This gap allows for thermal expansion.

Following these steps ensures a secure and durable joint between Aquasafe uPVC pressure pipes and fittings.