16 Jan 2025

Why Choose PE/PP Manhole Chambers?

The inspection, maintenance, and cleaning of drainage systems are essential to maintain their reliability. Manholes provide entry points for workers to identify and address blockages, leaks, or damages in underground pipes, ensuring the smooth functioning of wastewater and stormwater systems.

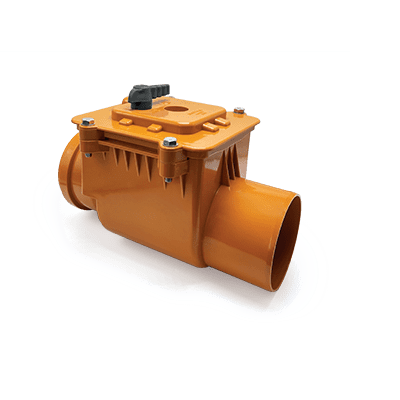

Opting for quality material ensures the safety and efficiency in the operation of drainage systems for years to come. Among the various options available, plastic manhole chambers made from Polyethylene (PE) and Polypropylene (PP) stand out due to their exceptional qualities. Here’s why you should choose PE/PP manhole chambers for modern drainage systems.

- Durability and Strength

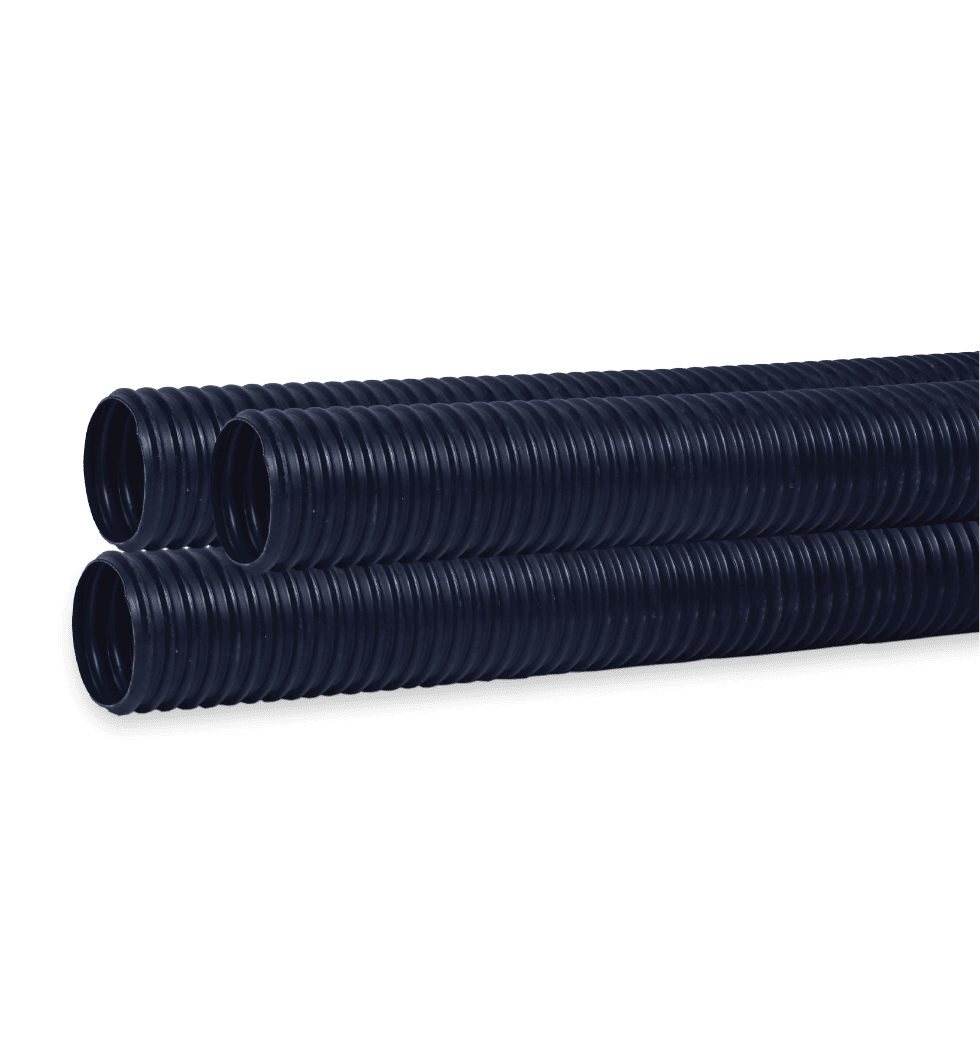

PE/PP manhole chambers are engineered to provide exceptional durability. Made from high-quality Polyethylene or Polypropylene, these chambers resist corrosion, chemical reactions and environmental degradation. Unlike traditional materials, they do not crack or deteriorate over time, making them ideal for long-term applications.

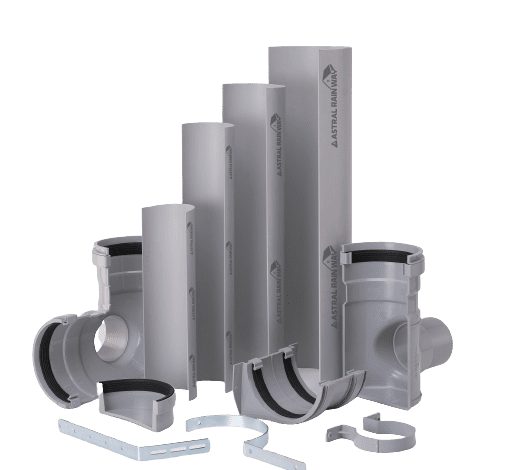

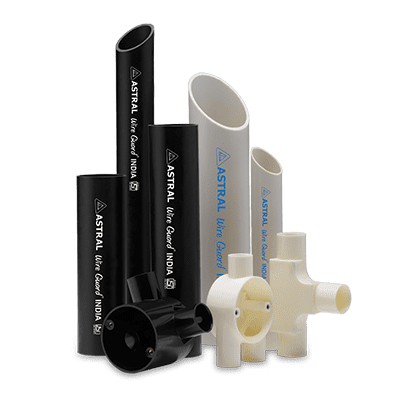

Plastic manhole chambers made of PE/PP, such as the Drain Hulk from Astral Pipes, are designed to withstand both on-road and off-road installations, proving their strength in various demanding site conditions.

- Lightweight and Easy Installation

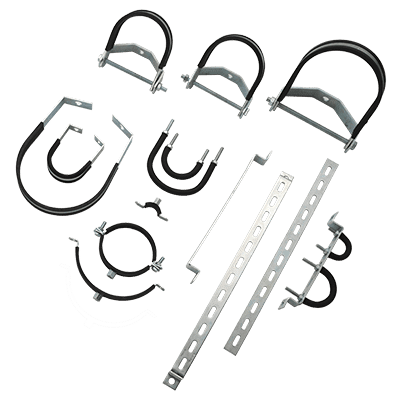

One of the most significant advantages of plastic manhole chambers is their lightweight nature. PE/PP manhole chambers are much easier to transport and install compared to their concrete counterparts. The lightweight design reduces labour and equipment costs, while also minimising the risk of workplace injuries during installation.

Additionally, the push-fit system used in PE/PP manhole cover assemblies makes the process quicker and more efficient, allowing for faster project completion.

- Watertight Joints

In drainage systems, ensuring that manhole chambers are watertight is important for avoiding leaks and groundwater contamination. PE/PP manhole chambers offer excellent hydraulic properties and watertight joints, which help prevent infiltration and exfiltration of water. This contributes to a more reliable and hygienic drainage system, which makes plastic manhole chambers a safer option for modern infrastructure.

- Low Maintenance and Cost-Effective

Plastic manhole chambers require minimal maintenance over their long lifespan. Their corrosion-resistant properties ensure they remain functional for years without the need for frequent repairs or replacements. This reduces overall maintenance costs, which makes them more economical in the long run. Additionally, these chambers have minimal excavation requirements during installation, further reducing the total cost of your project.

- Environmentally Friendly

PE/PP manhole chambers are made from recyclable materials, contributing to a more sustainable environment. Their long service life also means fewer replacements, which reduces the environmental impact of frequent material usage. Moreover, their resistance to environmental degradation ensures that they do not release harmful substances into the surrounding soil or water.

Choose a Reliable PE/PP Manhole Chambers

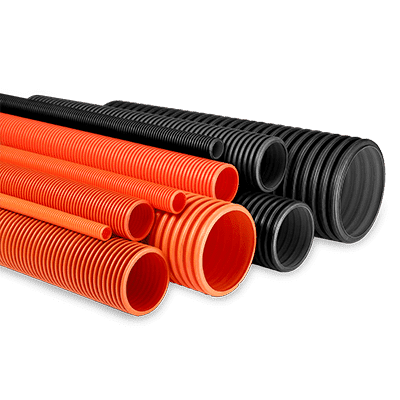

For those looking for a reliable option in manhole cover and chamber solutions, Astral Pipes’ Drain Hulk series is an outstanding choice. Made from 100% virgin UV-stabilized Polyethylene (PE) and Polypropylene (PP) material, Drain Hulk manhole chambers are designed to meet the high demands of underground drainage and sewerage systems. With innovative rib engineering, these chambers offer additional strength and act as an uplift prevention system in areas with high groundwater pressure.

The Drain Hulk chambers also feature watertight joints, which ensure maximum protection against leakage and contamination. Suitable for a variety of applications, from residential buildings to large-scale infrastructure projects like hotels, hospitals, and shopping malls, the Drain Hulk system offers long-lasting performance, minimal maintenance, and cost-effective installation.

-

16 Apr 2025

How to Install Water Tank? -

09 Apr 2025

Plastic Pipes vs Copper Pipes: Which One is Better for Plumbing? -

04 Apr 2025

Astral Pipes: Innovation, Quality, and a 25-Year Warranty You Can Trust -

31 Mar 2025

How to Calculate the Right Capacity of Your Home Water Storage Tank? -

25 Mar 2025

Why CPVC Pipes are the Best Choice for Hot Water?