Astral Drain Hulk: Comprehensive Solutions for Underground Drainage

Astral Drain Hulk represents the pinnacle of underground drainage systems, offering advanced manhole chambers and inspection chambers designed to meet the most demanding requirements across various sectors. From residential complexes to large municipal sewerage systems, Astral’s Drain Hulk system provides a versatile, reliable, and efficient solution that stands out in the market for its durability, ease of installation, and superior performance.

Applications of Astral Drain Hulk

Astral Drain Hulk is engineered to cater to a wide range of applications, which ensures robust performance in diverse environments. Whether it’s a residential property or a large-scale municipal sewerage system, Astral Drain Hulk manhole chambers and inspection chambers are designed to handle the challenges posed by different settings.

- Residential Applications

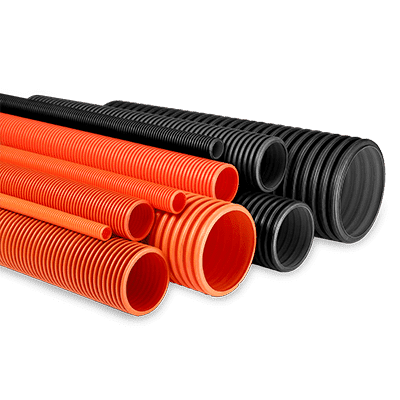

Astral Drain Hulk is ideal for residential homes and multi-floor buildings. The system ensures seamless and efficient drainage, reducing the risk of blockages and maintaining high standards of hygiene. The variety of available sizes, from Ø315 mm to Ø1000 mm, allows for flexibility in design and installation. This makes it suitable for both small and large-scale residential projects.

- Commercial and Institutional Applications

In commercial settings like hotels, resorts, hospitals, and shopping malls, Drain Hulk inspection chambers and manhole chambers provide reliable drainage solutions that can withstand high usage and traffic loads. The system is also perfect for academic institutions, where maintaining a clean and functional environment is crucial.

- Municipal Sewerage Systems

Astral Drain Hulk is a top choice for municipal sewerage systems due to its robust construction and ability to handle heavy loads. The system’s durability and resistance to environmental factors make it ideal for long-term use in public infrastructure projects.

Key Properties and Benefits

Astral Drain Hulk manhole chambers and inspection chambers are designed with advanced features that set them apart from conventional drainage systems. Here are some of the key properties and benefits:

- Great Flexibility

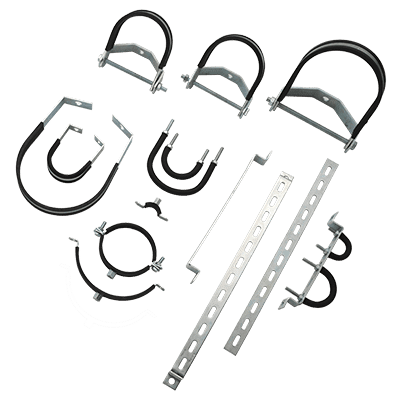

The availability of ready-made inspection chambers, long lengths of lighter-weight pipes, and various components make the installation of the Drain Hulk system fast and convenient. This flexibility is crucial in reducing installation time and labour costs. This makes it an efficient solution for large-scale projects.

- Hygienic and Safe

Astral Drain Hulk ensures trouble-free performance with joints that prevent blockages and leakage. This feature of the manhole chamber is vital for maintaining high standards of hygiene, especially in environments where sanitation is of utmost importance, such as hospitals and residential complexes.

- Perfect Hydraulic Properties

The chambers are designed with an in-built slope that enhances the hydraulic capabilities of the system. This design ensures efficient water flow, which reduces the risk of water stagnation and associated problems like odour and sediment buildup.

- Minimum Excavation Cost

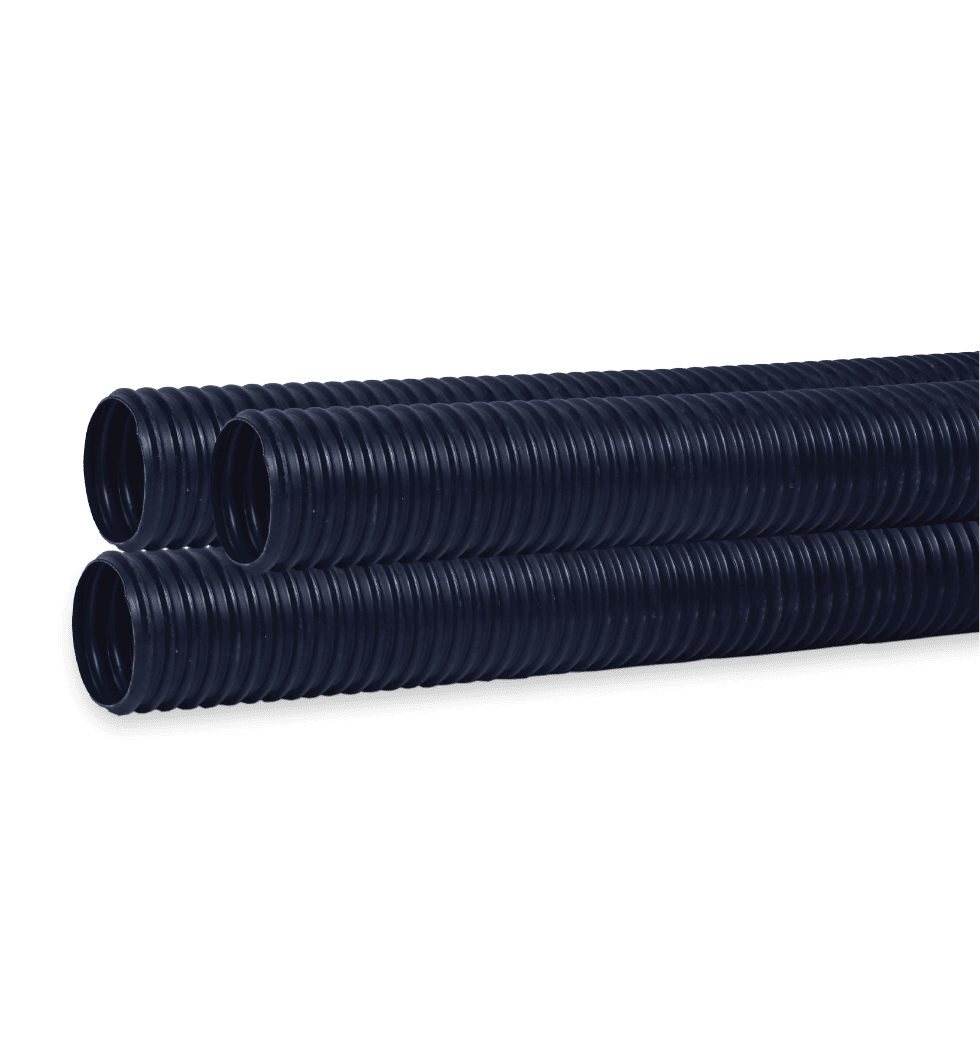

Thanks to the simple joining technique, the trench width required for installation can be kept to a minimum. Additionally, the smoother bore of the pipes allows for high flow rates at relatively flatter gradients, further reducing excavation and installation costs.

- Watertight System

The connection between the pipe, riser, or shaft and the chamber base is watertight, which ensures that there are no leaks. The design of the pipe joints with a click ring and sealing ring makes the system completely leak-proof, which is essential in preventing groundwater contamination.

- Maintenance-Free

The system’s optimum functional qualities, good hydraulic properties, and smooth surface finish reduce the need for regular maintenance, such as jetting. This feature not only lowers operational costs but also ensures that the system remains functional and reliable for an extended period.

- Great Strength & Durability

Astral Drain Hulk is sufficiently durable to meet site loading requirements. This makes it suitable for both on-road and off-road installations. The system’s strength ensures that it can withstand heavy loads and challenging environmental conditions without compromising its integrity.

- Longer Life and Overall Economy

Due to superior chemical resistance and durability, Astral Drain Hulk offers a long service life and trouble-free operation. This longevity, combined with the system’s efficiency and low maintenance requirements, makes it a cost-effective choice for long-term drainage solutions.

Installation Guidelines for Astral Inspection Chambers

Proper installation of inspection chambers is important to ensure the system’s effectiveness and longevity. Here is a step-by-step guide to installing Astral inspection chambers:

- Preparation

Begin by excavating the trench according to the specified dimensions. The trench should be 300 mm wider on all sides of the chamber and 150 mm deeper than the chamber invert depth. Compact the excavated base layer to 95% and lay a PCC (Plain Cement Concrete) layer of 150 mm height.

- Installing the Chamber Base

Place the inspection chamber base on the PCC layer and fill the gaps below the base with PCC. Ensure that the chamber is horizontally aligned by checking the levelling.

- Connecting the Inlet

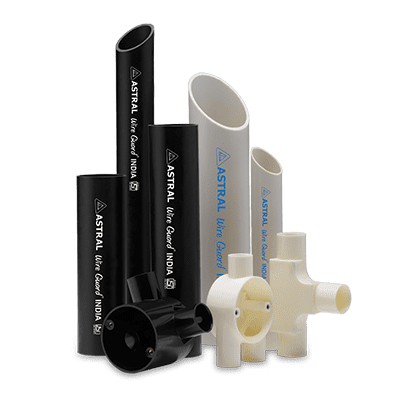

Drill the hole for the inlet pipe at the pre-marked positions using an Astral cup saw. Insert the inlet rubber seal and push the plain (spigot) end of the PVC pipe into the seal for a watertight connection. No glue or silicon is needed, making the process straightforward and efficient.

- Connecting the Outlet

The outlet connection is a spigot type. Slip the socket end of the PVC ring fit pipe onto the outlet connection and apply lubricant for smooth insertion. If necessary, cut off any unnecessary spigot at a right angle with a saw to ensure a proper fit.

- Assembly, Backfilling & Compaction

Ensure the chamber is level and aligned with the connecting pipes. Backfill around the chamber in layers of 300 mm, compacting each layer to 95% with a mechanical vibrating stamper. For greater stability, use gravel or sand for backfilling, as these materials have high permeability and absorb lateral thrust.

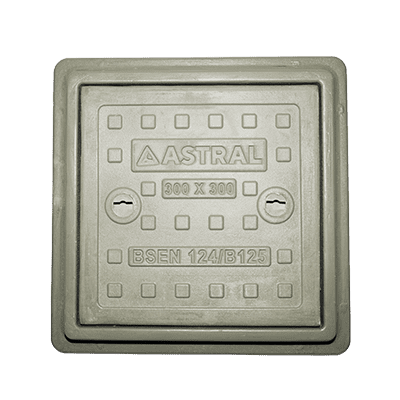

- Height Adjustment and Cover Installation

Adjust the chamber height on-site by cutting the upper edge of the chamber if necessary. Install the PE cover for non-traffic areas or a concrete load-bearing ring for traffic areas. The load should be absorbed by the frame and cover, not the chamber itself, to prevent damage.

Installation Guidelines for Astral Manhole Chambers

Installation of manhole chambers is an important process that must be done with precision to ensure the system’s long-term functionality. Here’s an overview of the installation procedure for Astral manhole chambers:

- Excavation

Excavate a trench 300 mm wider on all sides of the manhole chamber and 150 mm deeper than the manhole invert depth. Compact the excavated base layer to 95% and lay a 150 mm PCC layer on it. Place the manhole chamber on the PCC and fill the gaps below the base with PCC, ensuring horizontal alignment.

- Connecting the Inlet

To connect the inlet pipe, drill the appropriate diameter hole at the pre-marked positions, insert the inlet rubber seal, and push the plain end of the PVC pipe into the seal for a watertight connection. Astral seals allow for 5° movement in all directions, accommodating site constraints.

- Connecting the Outlet

The outlet connection is a spigot type. Slip the socket end of the PVC ringfit pipe onto the outlet connection and apply lubricant for smooth insertion. If required, trim the spigot for a proper fit.

- Assembly, Backfilling & Compaction

Check the levelling and alignment of the manhole chamber and connecting pipes. Backfill around the manhole chamber in 300 mm layers, compacting each layer to 95%. For increased load-bearing capacity, use gravel or sand as backfill material, as these materials absorb lateral thrust.

- Height Adjustment and Cover Installation

Adjust the height of the manhole chamber by cutting the upper edge if necessary. For traffic areas, install a concrete load-bearing ring around the neck of the chamber, avoiding direct contact with PCC and RCC. The frame and cover should absorb the traffic load, not the manhole chamber itself, to ensure durability.

Available Sizes of Astral Drain Hulk

Astral Drain Hulk offers a wide range of sizes for both inspection chambers and manhole chambers to meet the diverse needs of different applications:

- Inspection Chambers: Available in Ø315 mm, Ø355 mm, Ø450 mm, Ø500 mm, and Ø600 mm.

- Manhole Chambers: Available in Ø800 mm and Ø1000 mm, in both single-piece and modular designs (Base Unit + Riser Unit + Upper Unit).

This variety allows for flexibility in design and installation, ensuring that Astral Drain Hulk can meet the specific requirements of any project, from residential properties to large-scale municipal sewerage systems.

Astral Drain Hulk is a comprehensive and advanced solution for underground drainage and sewerage systems. With its superior manhole chambers and inspection chambers, Astral Drain Hulk offers unmatched durability, flexibility, and ease of installation. The system’s ability to handle heavy loads, maintain high standards of hygiene, and provide watertight performance makes it an ideal choice for a wide range of applications.