Description

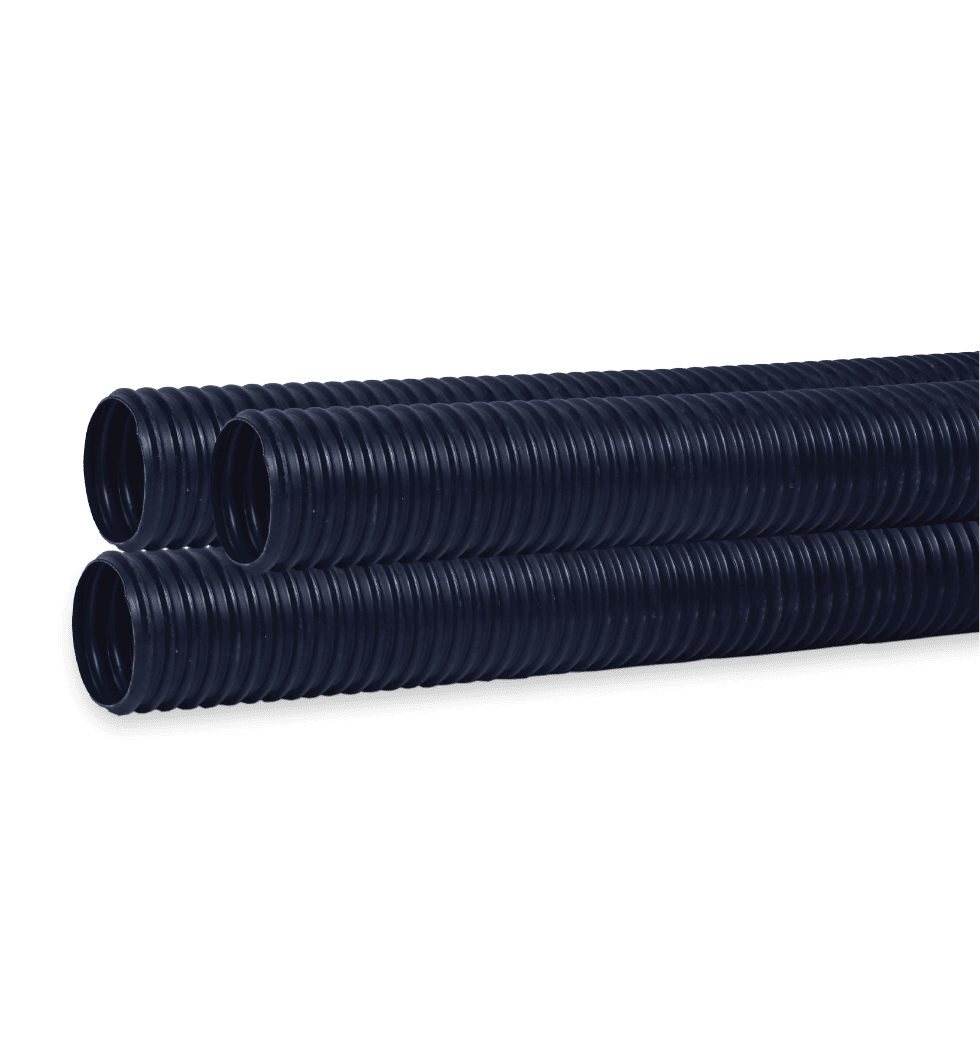

Corrugated PE Ducts for Pre-Stressing & Post-Tensioning Tendons

Pre-StiRex Corrugated Sheathing ducts are made from high-density polyethylene (HDPE), and serve a distinct purpose in the realm of internal bonded post-tensioning of tendons in pre-stressed concrete. These ducts find application in various projects, including flyovers, bridges, nuclear containments, offshore platforms, via ducts, underpasses, tunnels, and more.

The use of flat ducts becomes particularly popular in construction sectors where the utilization of round section ducts in post-tensioned slabs is impractical due to constraints posed by the slab thickness. These HDPE ducts provide an effective solution, allowing for efficient tendon placement and tensioning within the concrete structures. They contribute to the overall strength and durability of the construction, ensuring optimal performance in challenging environments and critical infrastructure projects.